Kadikis AV Ltd.

Industrial automation, development, repairs and restoration of manufacturing machines.

-

Projects

Utility post marking machine

Automatic measurement and marking of utility posts. Machine positions the post, measures it’s diameter and either nails a metal marking plate, or presses an identification microchip inside the board.

Tool carriage is positioned using Festo servo motor, the rest is controlled by Siemens S7-1200 PLC and Siemens touch panel.Servo system in action:

Vibration feeder for ID chips:

Client: Latvenergo (national electricity provider company), july 2016.Automatic feed of packed wood boards

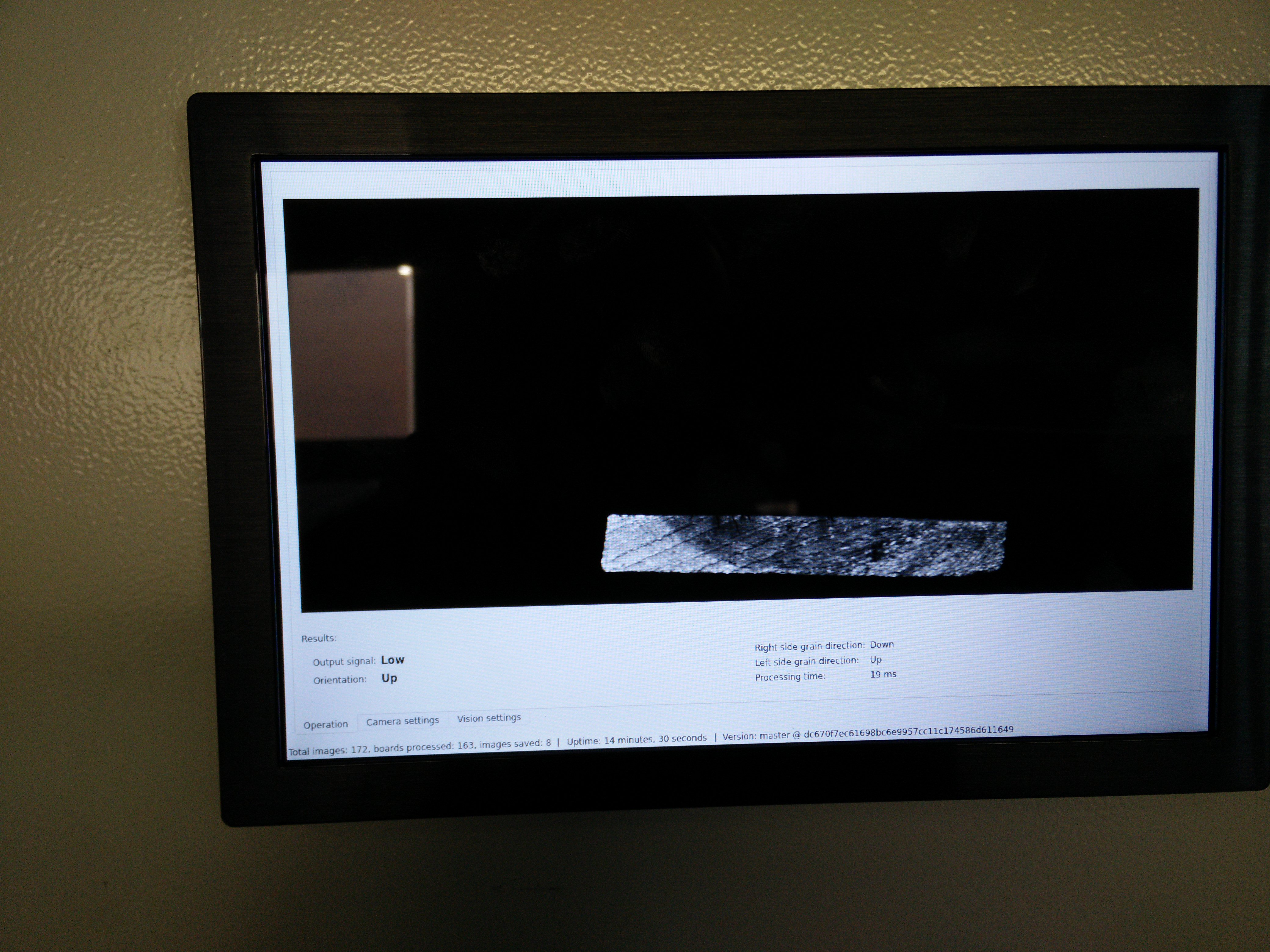

Machine performs automatic dismantling of packs of boards and feeds them into planer. All process is supervised by one person, which is only possible because of specially developed machine vision system. Cameras perform two tasks: